TKD type of

Si-PCD has hardness, strength, and toughness approaching that of

Co-sintered PCD but provides superior thermal stability. The ceramic

bonded composite is impervious to most corrosives. TKD Si-PCD can

compete with Versimax diamond composite with better wear out ratio but

much reasonable rate !

Features:

1,Silicon bond with EDM cutting diamond, it makes pure PCD cuttable to form any shape.

2,

High temperature bearing, Silicon bond solid pcd can bear higher

temperature at 1200 °C, while metal bond pcd only bear 700°C or so.

3, High wear ratio than any type of polycrystalline diamond, it achieves 3-4 times higher wear ratio than standard PCD/TSP.

4, High corrosion resistance and flexibility in producing complex shapes.

5, It can get high precision on the surface after polishing.

Usage:

Water

cutting sandtube, flue gas atomizer nozzles, wire drawing die etc,

also some automobile industry use this materials as well to achieve high

precision and high wear result.

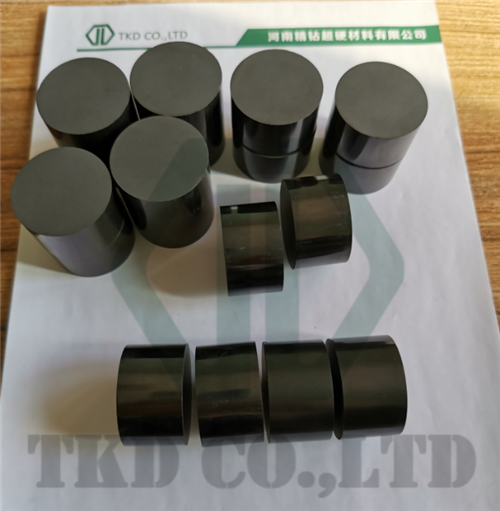

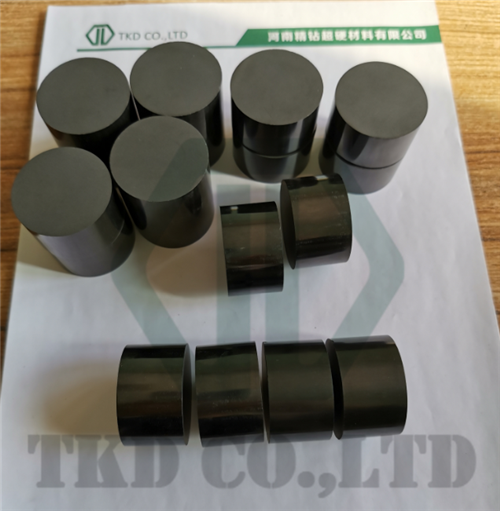

Size available:

D40x H30

D40 x H25

D30 x H30

D30 x H28 ....

We can form any shape as per EDM cutting method.

E-Mail: sale@tkd-hn.com

Whatsapp/wechat

Whatsapp/wechat