Introduction:

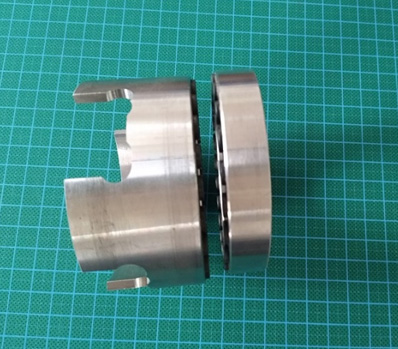

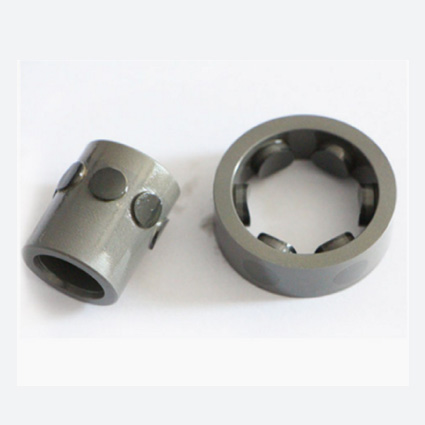

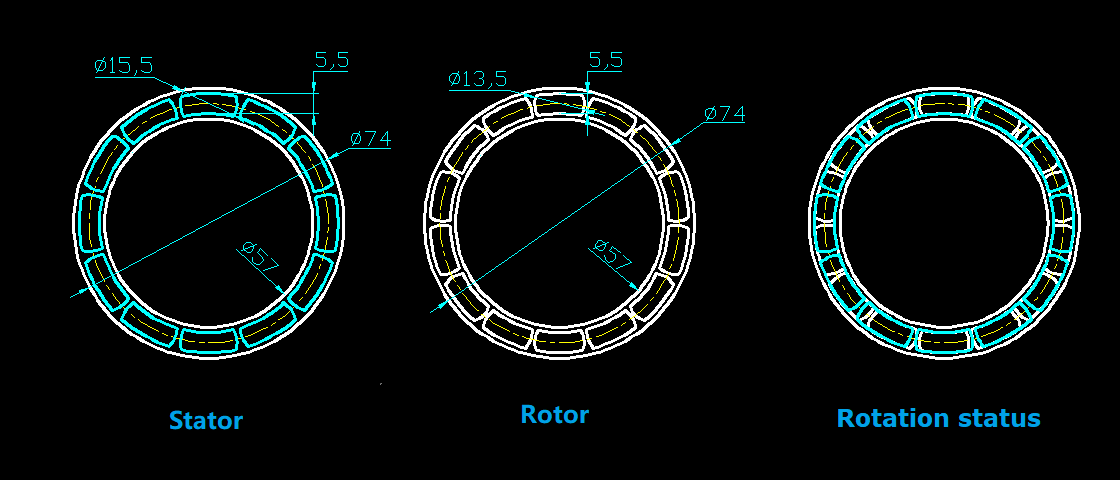

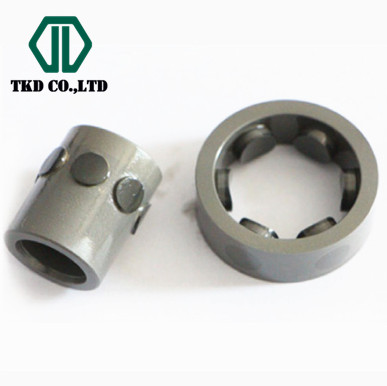

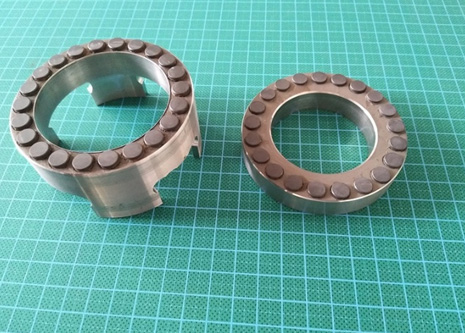

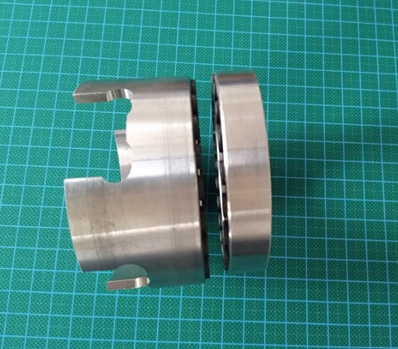

PDC Radial Bearing and thrust bearing sets include a rotor and stator bearing rings. These two rings oppose each other with the PCD surface on the inside diameter of one ring in direct contact with the PCD surface on the outside diameter of the ring.

It is new developed drilling motor wear parts, as we all know USS is the leader in diamond solutions, he is the leading producer and giant supplier for this item.

As per different clients strong request, our TKD PDC materials engineers group begins our study and teams up with one of domestic leader in engineered bearing organization to develop this item and try to offer breakthrough performance by using PDC insert bits.

Considering factors like heavy load, high speeds, working tough lubricant mud environment, high temperature etc, we work closely with each customer to listen to their requirement and design for the best solution of each application.

After 2 years development and experiment, we successfully breakthrough the technical challenge : well and precisely controlled the PCD insert brazing concentricity, squareness and Parallelism.

we are confident to say our PCD bearings now can work nicely and are qualified to meet clients needs now. Of course, there is still the quality GAP between USS and our PCD bearings.

But we never stop on the way to be the best !

Test method:

We have in-house lab testing method to keep the bearings work fine.

Also we share with local contracted drilling team site for experiment.

Type and size:

PDC radial bearing and PDC thrust bearing, available from 1”-10” in diameter. OEM is available as per client precise drawing.

Application:

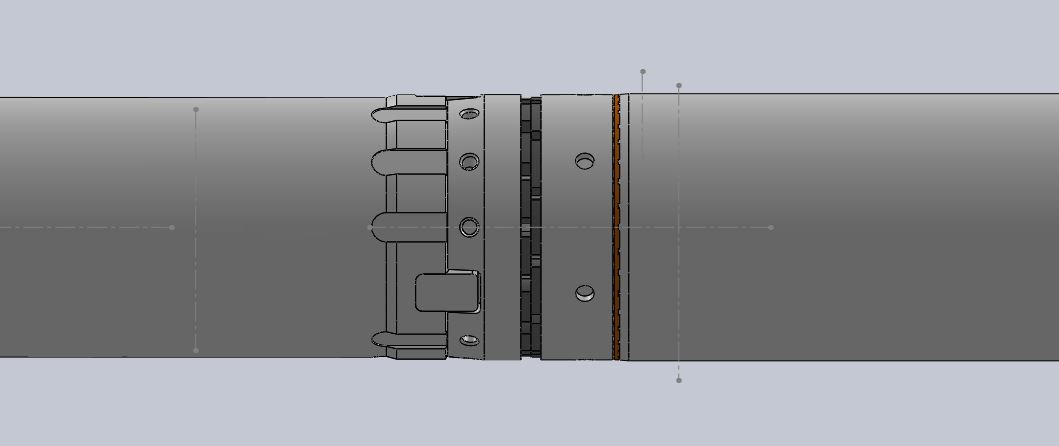

As anti-friction bearing for downhole motor, which is widely used in turbo drills, mud motors, electric submersible pumps and many other oil field applications.

Performance:

Compared with tungsten carbide bearing,

The PDC bearing has much longer tool life, its life is 5-10 times longer than tungsten carbide bearing, and it can also bear the increased load capacity.

Save long hours for changing bearings, save cost and efficient work !

Technical parameter:

| Properties | PCD insert | Tungsten carbide | Steel(4140) |

| Coefficient of Friction | 0.09 | 0.2-0.25 | 0.42 |

| Thermal conductivity(W/mk) | 543 | 67 | 42.6 |

| Fracture toughness | 13-15 | 10-20 | 50 |

| Hardness(Gpa) | 45.7 | 1.7 | 0.2 |

| Compressive strength(Gpa) | 6.9-7.6 | 2.68 | |

| Young's Modulus(Gpa) | 805 | 625 | 205 |

| Tensile Strength(Mpa) | 1150-1500 | 323 | 415 |

| Thermal stability | 650 °C |

We look forward to hearing from you with precise drawings and detailed requirement to make the reasonable quotation ! See below design example for what we offered the solution for one customer for a rotational rock drill used in mining.

Any requirement or technical aid from us, please go for Margaret

Whatsapp/wechat

Whatsapp/wechat